3 Axis Force Sensor VS 6 Axis Force Sensor

2024-07-23

In the realm of advanced robotics, manufacturing, and scientific research, force sensors play a pivotal role in enhancing precision, control, and safety. Among the various types of force sensors available, 3-axis and 6-axis force sensors are particularly prominent. These sensors are used to measure force and torque in multiple dimensions, providing critical data for a wide range of applications. This article explores the key differences between 3-axis and 6-axis force sensors, helping you understand their functionalities, applications, and advantages.

Understanding Force Sensors

3 Axis Force Sensor:

A 3-axis force sensor measures forces along three perpendicular axes: X, Y, and Z. This type of sensor captures linear forces in three dimensions but does not measure torque or rotational forces.

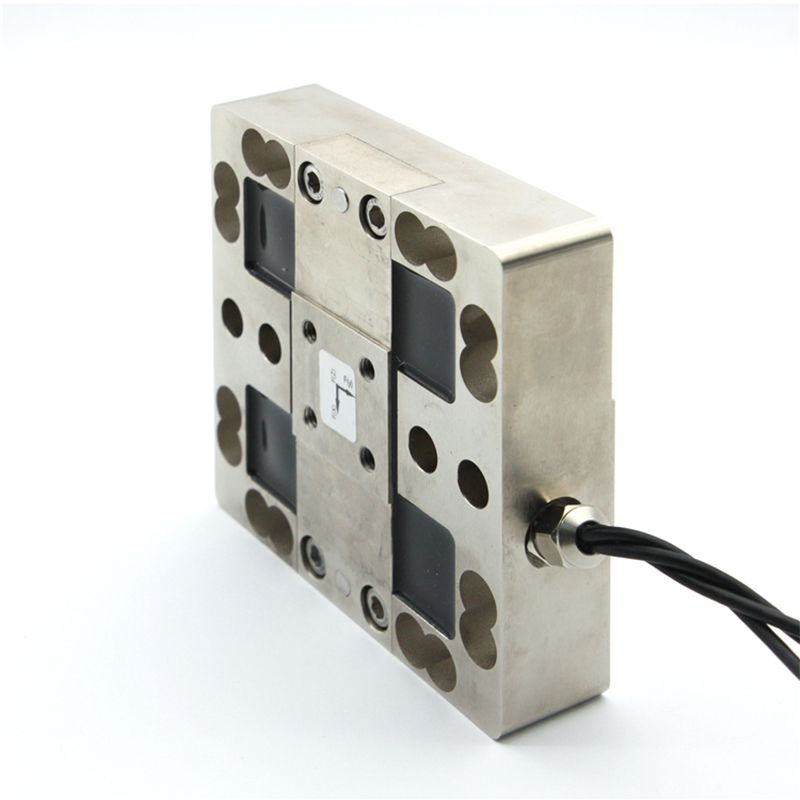

6 Axis Force Sensor:

A 6-axis force sensor, on the other hand, measures both forces and torques along three perpendicular axes: X, Y, and Z. This means it captures not only linear forces but also rotational forces (torques) around these axes, providing a comprehensive picture of the forces acting on an object.

Key Differences

Measurement Capabilities:

3 Axis Force Sensor: Measures linear forces in three dimensions (Fx, Fy, Fz).

6 Axis Force Sensor: Measures linear forces (Fx, Fy, Fz) and rotational forces (Mx, My, Mz), providing six degrees of freedom.

Complexity and Data Output:

3 Axis Force Sensor: Simpler in design and data output, focusing solely on three-dimensional linear forces. This makes them easier to integrate and interpret.

6 Axis Force Sensor: More complex, providing detailed information on both linear and rotational forces. This requires more sophisticated data processing and interpretation but offers a richer set of data.

Applications:

3 Axis Force Sensor: Ideal for applications where only linear force measurement is required. Common uses include material testing, robotic gripping, and basic force monitoring in industrial processes.

6 Axis Force Sensor: Essential for applications requiring comprehensive force and torque measurement. These sensors are widely used in advanced robotics (for tasks like precision assembly and haptics), biomechanics (analyzing human motion), aerospace (stress testing on components), and complex industrial automation.

Cost and Integration:

3 Axis Force Sensor: Generally less expensive and easier to integrate due to their simpler design and fewer measurement dimensions.

6 Axis Force Sensor: Typically more costly and requires more complex integration due to the additional measurement capabilities and data handling requirements.

Accuracy and Sensitivity:

Both types of sensors can be highly accurate and sensitive, but 6-axis force sensors usually offer higher precision in applications where understanding both linear and rotational forces is crucial. The additional axes of measurement can help detect subtle changes in force and torque that a 3-axis sensor might miss.

Choosing the Right Sensor

When deciding between a 3-axis and a 6-axis force sensor, consider the following factors:

1. Application Requirements: Determine whether your application requires only linear force measurements or both force and torque measurements. For instance, robotic arms performing complex manipulations would benefit from a 6-axis sensor, whereas a simple material testing setup might only need a 3-axis sensor.

2. Budget: Evaluate your budget and weigh it against the complexity and capabilities you need. 6-axis sensors, being more advanced, come at a higher cost.

3. Data Processing Capabilities: Ensure your system can handle the data output from the sensor. 6-axis sensors produce more data, necessitating advanced data processing and analysis capabilities.

4. Integration Complexity: Consider the ease of integrating the sensor into your existing system. If you need a straightforward solution, a 3-axis sensor might be more suitable.

In all, Both 3-axis and 6-axis force sensors have their unique advantages and are suited to different applications. While 3-axis sensors are sufficient for basic linear force measurements, 6-axis sensors provide comprehensive force and torque data essential for advanced applications in robotics, biomechanics, and aerospace. Understanding the specific needs of your application will guide you in selecting the right sensor, ensuring optimal performance and accuracy in your projects.

RELATED NEWS

-

Axis Force Sensors Gain Momentum as Precision Engineering Demands Surge

Axis force sensors are becoming essential components across multiple high-tech industries as companies push for higher accuracy, safer automation, and smarter system feedback. From robotics to aerospace, these advanced sensors—capable of detecting force across one or more axes—are reshaping how machines interact with the physical world.

-

Rising Demand for 2-Axis Force Sensors as Precision Automation Expands

As global industries continue to push toward smarter manufacturing and higher automation standards, the 2-Axis Force Sensor is emerging as a vital tool across multiple sectors. Known for its ability to measure force in two perpendicular directions simultaneously, this compact and reliable sensor is gaining widespread adoption in applications that require precision, stability, and real-time feedback.

-

Multi-Axis Force Sensors Gain Momentum as Precision Automation Advances

As automation, robotics, and intelligent manufacturing continue to accelerate worldwide, demand for high-precision axis force sensors is rapidly increasing. These advanced sensing devices—ranging from 2-axis force sensors to 3 axis force sensors and even 6 axis force sensors—are becoming essential tools for industries that require accurate, real-time force measurement and improved operational safety.

-

UF debuts at Taichung Machine Tool and Smart Manufacturing Exhibition

UF will participate in the "Taichung Machine Tool and Smart Manufacturing Exhibition", which will be held from November 26 to November 29 at the Taichung International Convention and Exhibition Center, booth number 3100.

-

New Developments In Sensor Technology

Sensor technology is constantly developing with the development of technology, and new sensors have been miniaturized, systematic, and networked, promoting the development of the society and economy.

-

![Taipei Nangang Exhibition Hall [Second Hall Q1408]](//d.hzytb.com/images/20250818/135957/460999.jpg?imageView2/1/w/396/h/225)

Taipei Nangang Exhibition Hall [Second Hall Q1408]

We invite you to visit us at Taipei Nangang Exhibition Center, Hall 2, Booth Q1408.

-

Taichung Industrial Automation Exhibition 2025——Taiwan Ultraforce Measurement and Control System Co., Ltd.

Taiwan Ultraforce Measurement and Control System Co., Ltd. (Ultra Force) specializes in high-precision force sensor development and manufacturing, with over 20 years of German sensor design experience.

-

What Is a 6-Axis Force Torque Sensor

A 6-axis force torque sensor is a sophisticated device that can simultaneously measure three-dimensional force (X, Y, Z) and three-dimensional torque (rotational force around each axis). Unlike single-axis or basic sensors, this type provides a complete picture of interaction forces in all directions, making it indispensable for tasks requiring high sensitivity and dynamic feedback.

-

The Expanding Applications of Torque Sensors: Driving Precision Across Industries

As automation and intelligent machinery become increasingly central to modern manufacturing, medical devices, and mobility systems, torque sensors have emerged as critical components driving safety, efficiency, and precision. These devices measure the rotational force (torque) applied to a shaft or system and are widely used to optimize mechanical performance and prevent failure in real-time operations.

-

What Does the Force Sensor Do

Force sensors may be small in size, but their impact is enormous across industries. So, what does the force sensor do, and why is it such a critical component in today’s technology?

-

Which Is Better: Load Cell or FSR

As industries increasingly rely on accurate force measurement for automation, robotics, and wearable technology, one key question often arises: Which is better—load cell or FSR (Force Sensing Resistor)? The answer depends on the application, as both sensors offer unique advantages.

-

How Does a Tension Force Sensor Work

In the age of smart manufacturing and structural safety monitoring, tension force sensors are playing a vital role in ensuring accuracy, efficiency, and safety across numerous applications. But how does a tension force sensor actually work?

-

Unlocking Precision: The Expanding Applications of Robot Joint Torque Sensors in Smart Automation

As robotics continues to revolutionize modern industry, the robot joint torque sensor has emerged as a key component enabling smarter, safer, and more adaptive machines. From collaborative robots on factory floors to surgical robots in operating rooms, these sensors are making robotic motion more responsive and human-like than ever before.

-

How Do Self-Calibrating Torque Sensors Prevent Robotic Arm Drift in Space Missions

In the weightless, frictionless environment of space, maintaining precise control over robotic arms is a critical challenge. Even the smallest deviation—known as robotic arm drift—can result in mission delays or equipment damage. To address this, ULTRAFORCE has unveiled a breakthrough in motion control: self-calibrating torque sensors, a technology poised to transform how robotic systems operate in space.

-

How to Check a Load Cell

Load cells are essential components in weighing systems, converting mechanical force into electrical signals for accurate measurements of weight and force. However, like any precision instrument, load cells can experience issues over time, such as drifting calibration, electrical malfunctions, or physical damage. To ensure they continue to function properly, it's important to periodically check their condition. Here's a guide on how to check a load cell and diagnose common issues.

-

What is the Difference Between a Weight Sensor and a Load Cell?

The terms "weight sensor" and "load cell" are often used interchangeably, but they are not exactly the same thing. While both are essential components in measuring force, weight, or load in various applications, they serve slightly different roles in the measurement process. Understanding the distinction between a weight sensor and a load cell can help clarify how each functions and where they are used.

-

What is a Load Cell Weight Sensor?

A load cell weight sensor is a critical component used in weighing systems to measure force or weight. It operates based on the principle of converting mechanical force into an electrical signal, which can then be quantified and processed. These sensors are integral to a wide variety of industries, from industrial manufacturing to healthcare, transportation, and even in everyday household devices.

-

How Do You Measure Weight with a Load Cell?

A load cell is an essential component for measuring weight or force in various industries, from manufacturing to healthcare. Essentially, a load cell converts mechanical force or weight into an electrical signal that can be easily measured and recorded. But how exactly does this process work? Let’s break it down.

-

Application Prospects of Robot Joint Torque Sensor

With the rapid development of industrial automation and artificial intelligence technology, robots are increasingly used in various fields such as manufacturing, medical care, and services. In one of the core components of robotics technology, the role of joint torque sensors has become increasingly important in the drive system.

-

Application prospects of 3-axis force sensors: improving industrial precision and intelligence

With the continuous development of industrial automation and intelligence, 3-axis force sensors, as precision measuring equipment, are gradually showing great application potential in multiple industries. This sensor can simultaneously measure the force of an object in three directions, making it widely used in precision operations, product quality control, robotics and other fields.

-

Introducing the MT510 3 Force Sensor from ULTRAFORCE MEASUREMENT AND CONTROL SYSTEM

The MT510 3 Force Sensor is the latest innovation from ULTRAFORCE MEASUREMENT AND CONTROL SYSTEM, designed to meet the demanding needs of modern industries requiring precise force measurement. This advanced sensor provides accurate and reliable data for various applications, including robotics, automation, and material testing.

-

How Does a Load Cell Measure Weight?

Load cells are crucial devices used in various applications to measure weight and force with precision. A weighing load cell operates based on the principle of converting mechanical force into an electrical signal. Typically, these cells are made from materials like aluminum or steel, which are both durable and capable of withstanding significant loads.

-

Load Cells for Tanks: Enhancing Accuracy and Efficiency in Storage

In industrial applications, the ability to accurately measure and monitor the weight of materials stored in tanks is crucial. Load cells have become a vital component in achieving this goal, providing precise weight measurements for various substances, from liquids to solids. As industries look for ways to optimize operations, the use of load cells for tanks is gaining prominence.

-

What is a 6-Axis Force Sensor?

In the realm of modern technology, the demand for precision and accuracy in various applications has led to the development of advanced sensing solutions. Among these, the 6-axis force sensor has emerged as a critical tool in fields ranging from robotics to aerospace. But what exactly is a 6-axis force sensor, and how does it work?

-

How Do Compression Force Sensors Work?

In the ever-evolving landscape of industrial technology, compression force sensors have emerged as critical tools for measuring force and load in various applications. Understanding how these sensors operate is essential for engineers and manufacturers looking to enhance precision in their processes.

-

Understanding Compression Force Sensor Prices

Compression force sensors are vital instruments used in various industries to measure the amount of force exerted on an object. These sensors are commonly found in applications ranging from manufacturing to aerospace, providing critical data for quality control, safety, and operational efficiency. As with any technology, the price of compression force sensors can vary significantly based on several factors.

-

Can Load Cells Measure Tension?

In the world of precision measurement, load cells have long been celebrated for their ability to measure weight and force. However, a common question arises: can load cells effectively measure tension? The answer is a resounding yes.

-

What is the Difference Between a Force Sensor and a Pressure Sensor?

In the rapidly advancing field of technology and engineering, sensors play a crucial role in measuring and interpreting various physical phenomena. Among these, force sensors and pressure sensors are two distinct types, each designed for specific applications and functions. Understanding the differences between them is essential for engineers, researchers, and anyone interested in the intricate world of measurement technologies.

-

What is the Difference Between a Force Sensor and a Torque Sensor?

In industrial applications and engineering, force sensors and torque sensors are essential for measuring different types of physical inputs, but they serve distinct purposes. While both sensors are designed to measure mechanical quantities, their functions, and the way they operate, differ fundamentally.

-

How Does a Tension Sensor Work?

Tension sensors play a crucial role in industries where precise force measurement is essential. These sensors are designed to measure the tension, or the pulling force, exerted on a material, such as a wire, cable, or sheet, ensuring accurate control in various manufacturing and industrial processes. But how do they work?

-

Analysis of digital indicator price trends: Technological progress and market demand drive price changes

In recent years, price fluctuations in the digital indicator market have attracted much attention. With the continuous advancement of technology and the increase in demand for industrial automation, the prices of digital indicators are also constantly adjusting to adapt to market changes.

-

What is the role of Digital Indicator?

Digital Indicator is a device used to measure and display numerical information. It is widely used in industries, manufacturing, laboratories, etc. Its main functions include:

-

Customize Force Sensors with ULTRAFORCE MEASUREMENT AND CONTROL SYSTEM

ULTRAFORCE MEASUREMENT AND CONTROL SYSTEM is a leader in providing high-quality, customized force sensors tailored to meet specific industrial needs. Force sensors are essential in various fields, including robotics, automotive, aerospace, and medical devices, where precision and reliability are critical.

-

New waterproof amplifier unveiled to help industrial applications in harsh environments

With the growing demand for high-performance equipment in industrial sites, a new generation of amplifiers has emerged. This amplifier not only has powerful signal amplification functions, but also combines advanced protection design to ensure excellent performance in extreme environments, making it an important equipment in industrial production.

-

What is a 3 Axis Force Sensor?

A 3 Axis Force Sensor is an advanced measurement device that can detect and record the magnitude and direction of force in three directions simultaneously. Unlike traditional single-axis sensors, 3 Axis Force Sensors provide more comprehensive force data, making them excellent in complex application scenarios.

-

Dynamic Torque Sensor: Revolutionizing Precision Measurement

In the evolving landscape of industrial technology, the dynamic torque sensor is making waves with its advanced capabilities. Unlike traditional torque sensors, which measure static or average torque, dynamic torque sensors are designed to handle rapidly changing torque measurements with high precision. This makes them invaluable for applications where real-time torque data is crucial.

-

How Does a Force Torque Sensor Work? Unveiling the Mechanics Behind Precision Measurement

In the ever-evolving landscape of technology and engineering, the force torque sensor stands out as a marvel of precision and versatility. This sophisticated device plays a critical role in a multitude of applications, from robotics to aerospace, by measuring both the force and torque applied to an object. Understanding the workings of this sensor is key to appreciating its significance in modern technology.

-

Is a force sensor the same as a pressure sensor?

In the realm of measurement technology, force sensors and pressure sensors are often discussed, but they serve distinct purposes. Understanding their differences is crucial for selecting the right sensor for specific applications.

-

When should you use a junction box

A junction box is an often overlooked but essential component in electrical installations. But have you ever wondered exactly when it's necessary to incorporate one?

-

What Are the Three Types of Junction Boxes?

Junction boxes are critical components in electrical systems, designed to house and protect wire connections. They come in various types, each suited for different applications. Here are the three main types of junction boxes:

-

Where Do You Need a Junction Box?

Junction boxes play a crucial role in electrical systems, offering both safety and organization. But where exactly are they needed? Here’s a closer look at their essential applications.

-

What is a Junction Box?

In electrical installations, a junction box is a vital component that protects and organizes wire connections in a circuit system. In simple terms, a junction box is a small enclosure that houses the connection points for cables and wires to ensure a safe and tidy wiring environment.

-

Torque Sensor Knowledge Dry Goods Sharing

In life, I think everyone has encountered such problems. The torque sensor is faulty. Once the torque sensor fails, it will bring a lot of trouble. If it is serious, there will be a traffic accident! So be careful. Found that this torque sensor is broken, to be repaired in time.

-

What Are The Advantages And Disadvantages Of Torque Sensors?

Torque sensor, also known as torque sensor, torque sensor, torque sensor, torque meter, divided into dynamic and static two categories, of which dynamic torque sensor can also be called torque sensor, non-contact torque sensor.

-

What is a Force Sensor? What Types Are There?

Force is the direct cause of changes in the motion of matter. A force sensor can detect various mechanical quantities such as tension, pull, pressure, weight, torque, internal stress, and strain.

-

Characteristics and Working Principle of Torque Sensors

Torque sensors have quickly become an essential component in various industries, establishing themselves as an indispensable part of the sensor family.

-

What is a Torque Sensor?

A torque sensor is a device used to detect the torque on various rotating or non-rotating mechanical parts.

-

Characteristics and Working Principle of Torque Sensors

The emergence of the torque sensor itself should be used in all walks of life in a short time and become an indispensable variety in the sensor series.

-

What is Micro Torque Sensor

Micro Torque Sensor is a sensor used to measure very small torque. It is usually used in precision measurement and control applications, such as in robotics, precision machinery, automotive engine management, medical equipment and laboratory instruments. This sensor can detect and convert tiny torque values into readable signals, which can be further used for feedback control, data analysis or research.

-

Explore the mystery of multi-axis force sensors: black technology for accurate measurement of multi-dimensional force

In today's era of rapid technological development, sensor technology has penetrated into all aspects of our lives. Among them, multi-axis force sensors, as an innovative technology, are gradually attracting widespread attention. This article will unveil the mystery of multi-axis force sensors for you and take you to appreciate its unique charm in the field of multi-dimensional force measurement.

-

Explore Bellow Type Load Cell: Principles and Applications

Bellow Type Load Cell plays an indispensable role in modern industry and measurement technology. This sensor is not only known for its high precision and stability, but also widely used in various occasions where accurate weight measurement is required. So, what is Bellow Type Load Cell?

English

English 繁體中文

繁體中文 Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi Pilipino

Pilipino Gaeilge

Gaeilge عربى

عربى norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski Српски

Српски Afrikaans

Afrikaans icelandic

icelandic Беларус

Беларус Монгол хэл

Монгол хэл Hawaiian

Hawaiian Javanese

Javanese

![Taipei Nangang Exhibition Hall [Second Hall Q1408]](http://d.hzytb.com/images/20250818/135957/460999.jpg?imageView2/1/w/396/h/225)